As AM grows, this number will surely increase, further motivating companies like ABB to accommodate their new customer base. In other words, many makers of industrial robotic arms have begun to catch on to the growing adoption of their products for 3D printing. Therefore, as AM becomes more widely adopted in a factory setting, robotics companies have a greater incentive to find ways to work with AM technology.

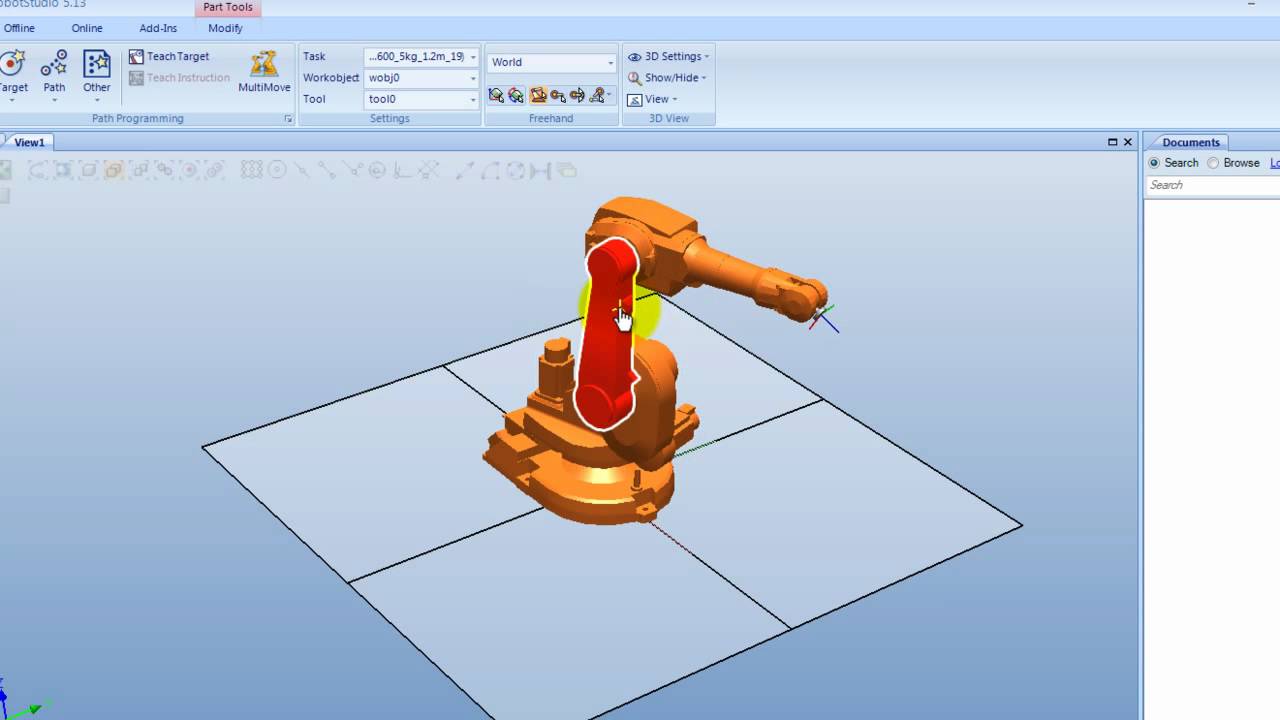

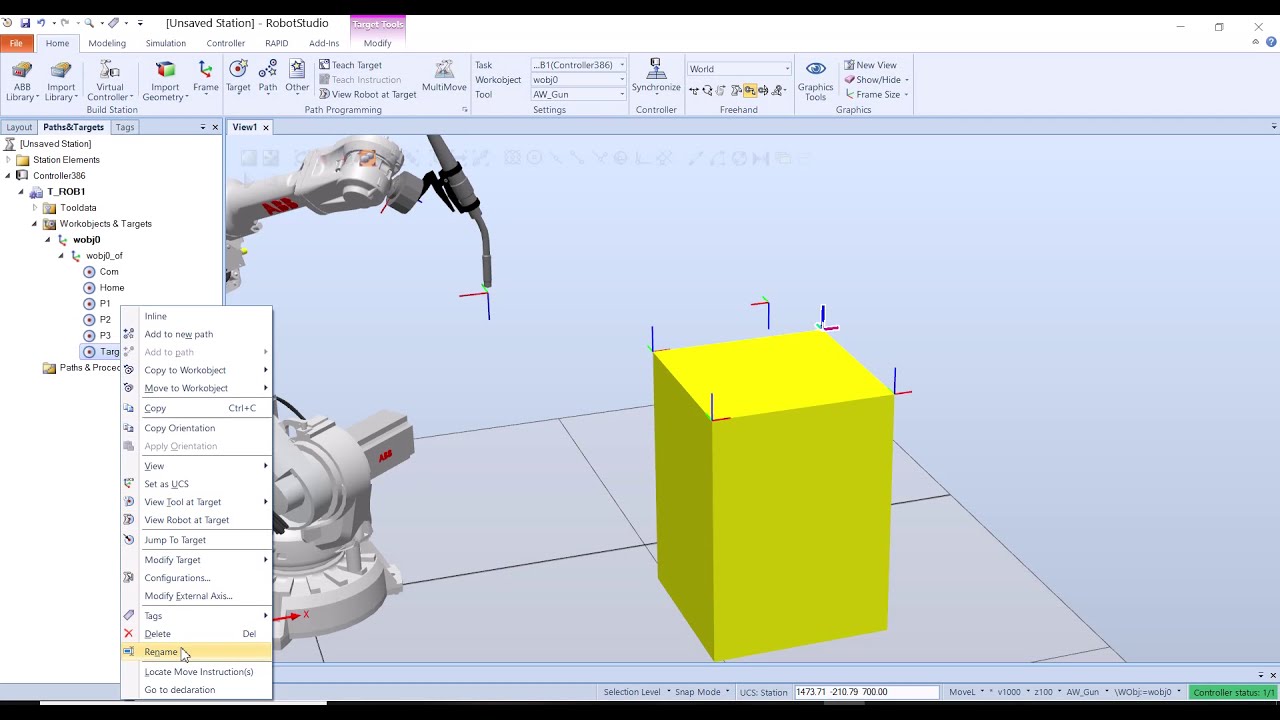

The drive for the use of these machines is not just the fact that many of them can be used to fabricate large-scale structures, but also that they would be more easily integrated into an already existing manufacturing environment, where industrial robots are already the norm. Comau and KUKA are comparable to ABB in terms of the way that their robots have been used for AM, while Universal Robots sells less expensive, less industrial machines that have been used by the likes of Voodoo Manufacturing. Of these, FANUC is the only one to sell a system specifically for 3D printing, a collaborative wire arc welding robot. Other companies who have seen their robotics featured in AM processes include Yaskawa, Comau, KUKA, Universal Robots, FANUC and Schunk. Despite its size and legacy, it is not the only manufacturer competing in the 3D printing space. The company suggests that this process is faster than plotting a toolpath for a traditional printing system.Įstablished over 130 years ago, ABB has roughly 147,000 employees spanning more than 100 countries. This includes such 3D printing processes as welding, concrete or printing with polymer granules.ĪBB highlights the fact that any 3D printing slicer software can be converted into ABB’s simulation environment and robot code. According to the company, the software’s new 3D printing feature will allow users to program ABB robots for AM in just 30 minutes. Part of the PowerPac portfolio, RobotStudio removes the need for manual programming for 3D printing. You’ll also come across countless researchers taking advantage of these robots for new 3D printing applications.Ĭlearly catching on to the growing adoption of its tools in the additive manufacturing space, ABB is hoping to make it easier for users to do so. Viridis3D also uses a standard ABB robot to perform a unique take on 3D printing sand for metal casting. One of the most notable may be MX3D, which outfitted its industrial robotic arm with a wire arc welding system to 3D print large-scale metal objects, including a bridge in Amsterdam.

Numerous customers have already begun using ABB robots for 3D printing purposes. Swiss tech giant ABB has caught on and has added 3D printing capabilities to the latest edition of its RobotStudio simulation and offline programming software. Their great dexterity and flexibility have made them increasingly powerful platforms for a variety of 3D printing processes. Industrial robotic arms are no strangers to 3D printing.

0 kommentar(er)

0 kommentar(er)